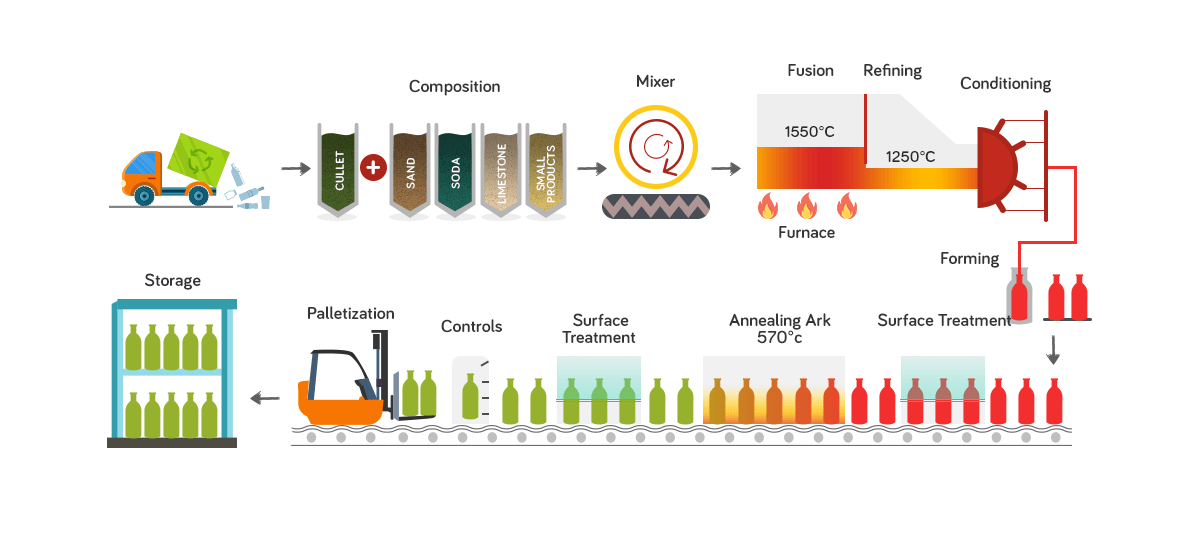

Manufacturing Process

The manufacturing process includes 8 steps:

Heat department

1Composition

The glass composition contains sand, limestone and soda ash. These ingredients are then mixed with cullet (recycled broken glass) in very precise proportions that make up the melting blast. The mixture is then poured into the furnace.

2Fusion

Our furnace uses a temperature of about 1,500 °C to heat the mixture and create then molten glass. The molten glass is homogenized and conveyed in conditioning channels allowing it to be sent to machines with the appropriate temperature and viscosity necessary for shaping the object. The glass takes about 24 hours to come out of the oven and be ready for forming.

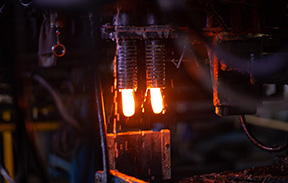

3Forming

Then the glass is sheared from feeders and cut into series of drops where it’s delivered to feed the production machines. At SEVAM, 3 molding processes are used for shaping, depending on the type of object:

Pressed

Pressed Pressed/blown

Pressed/blown Blown/blown

Blown/blown

4Annealing

After forming and slowly cooling hot glass objects (manufacture process), it comes the step where they must be heated and gradually cooled in an annealing arch (about 570 °C) in order to relieve residual internal stresses and eliminate any tension to strengthen the glass.

Cold department

5Quality control

After the annealing process, the glass must be controlled manually and/or by a control machine to apply cleaning procedures and enhance object quality. This process allows complying the international food and safety standards and also meeting SEVAM’s customer needs. The glass objects rejected by the control machine will be entirely reused as a raw material of cast iron.

6Decoration

The technique used for decoration is called screen printing. This process involves applying enamel frits for ceramic decoration on the object through a mesh screen and then tempered in a decorative arch heated around 580 °C.

7Conditioning and palletizing

Conditioning process comes at the end of the manufacturing line, it helps to group, maintain and protect glass objects in order to ensure better transport, storage, identification and delivery conditions.

8Storage and shipping

Once posed on a pallet, the object is then ready to be stored and shipped to the end customer.